Adaptable. Efficient. Profitable.

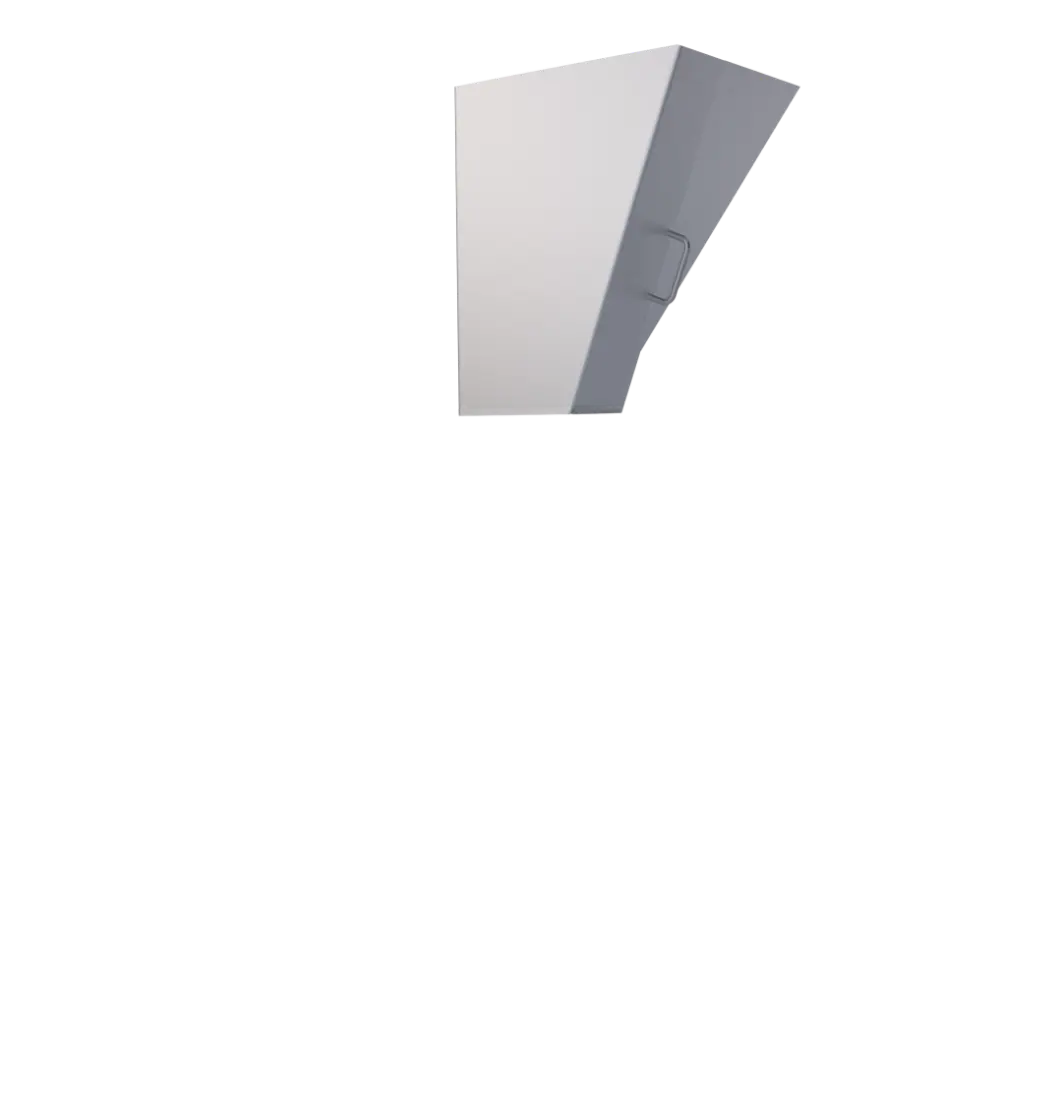

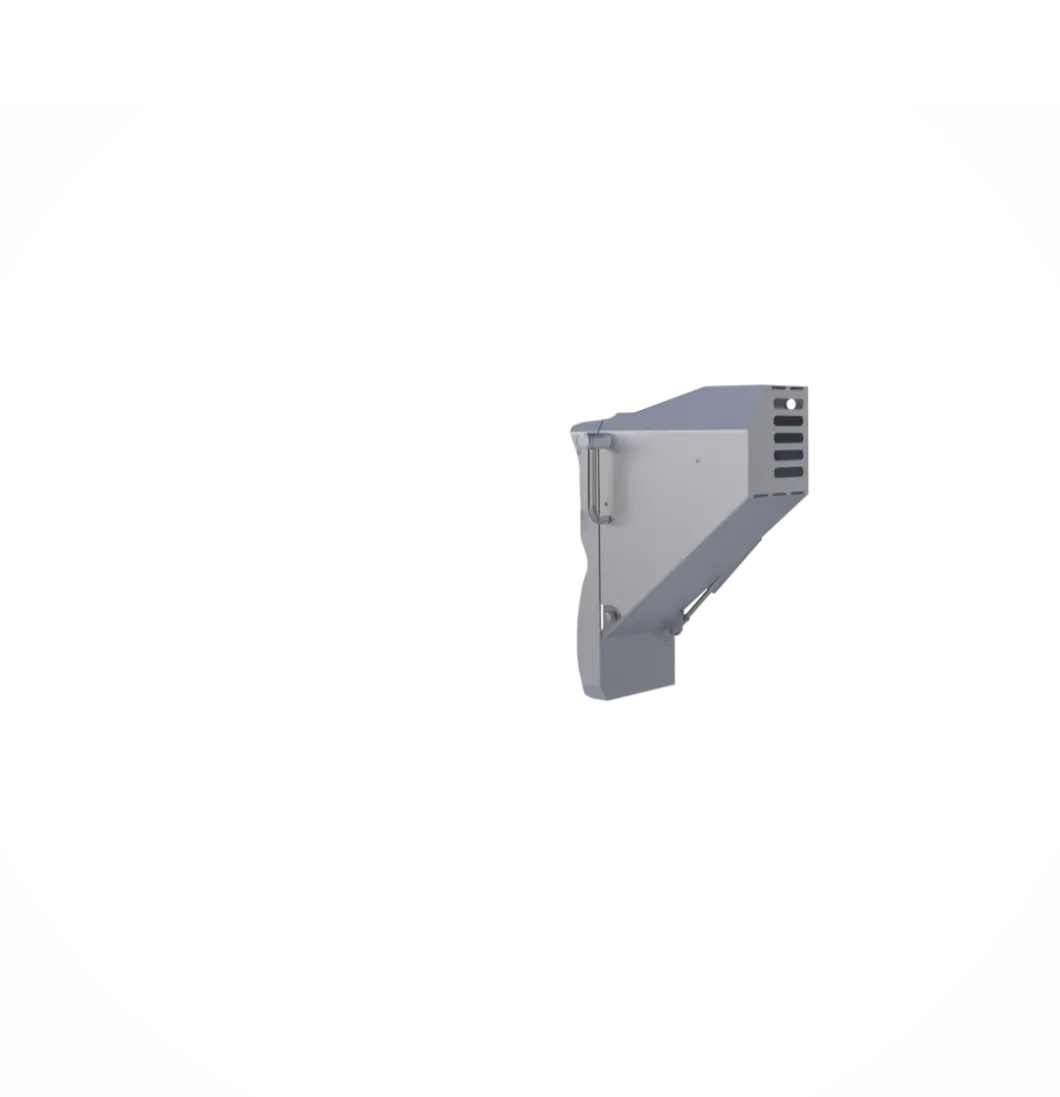

The AllMaxx S delivers precise separation, fast cleaning, and modular flexibility — all in one compact, German-engineered unit.

Performance That Matters

More output. Less waste. Built for change.

The AllMaxx S is engineered for processors who need consistent results, fast ROI, and minimal complexity — without being locked into rigid systems.

- Efficient product recovery with gentle, pressure-controlled separation

- Full washdown in approx. 2 minutes thanks to open-frame design

- Modular configuration adapts to evolving production demands

- Flexible throughput from 500 kg/h to 5 t/h, depending on product

One Machine. Many Applications.

Adaptable by design. Trusted across industries.

Whether you process poultry, meat, fish, plant-based, or pet food — the AllMaxx S delivers reliable, repeatable performance with minimal waste.

- Meat: pork trimmings, sausage mass, beef mince, beef, pork, etc.

- Poultry: trim, skin, MDM, rework, carcasses, wishbones, trimmings

- Fish: whitefish, salmon, rework, pre-cooked, mainframes, trimmings

- Plant-based: textured proteins, soft-fiber fruits

- Pet food: pâté, dense mixes, high-quality pet food with good structure and minimal particles

- Recycling: yogurt, plastic packaging and off-spec products

Modularity & Configuration

Configure it your way.

Adapt the AllMaxx S to your production with plug-and-play modules — no costly retrofits or specialized service needed.

Smarter Processing. Lasting Results.

Solutions that adapt. Performance that endures.

At AF Food Technology, we focus on helping you work cleaner, reduce waste, and simplify operations — with results you can measure.

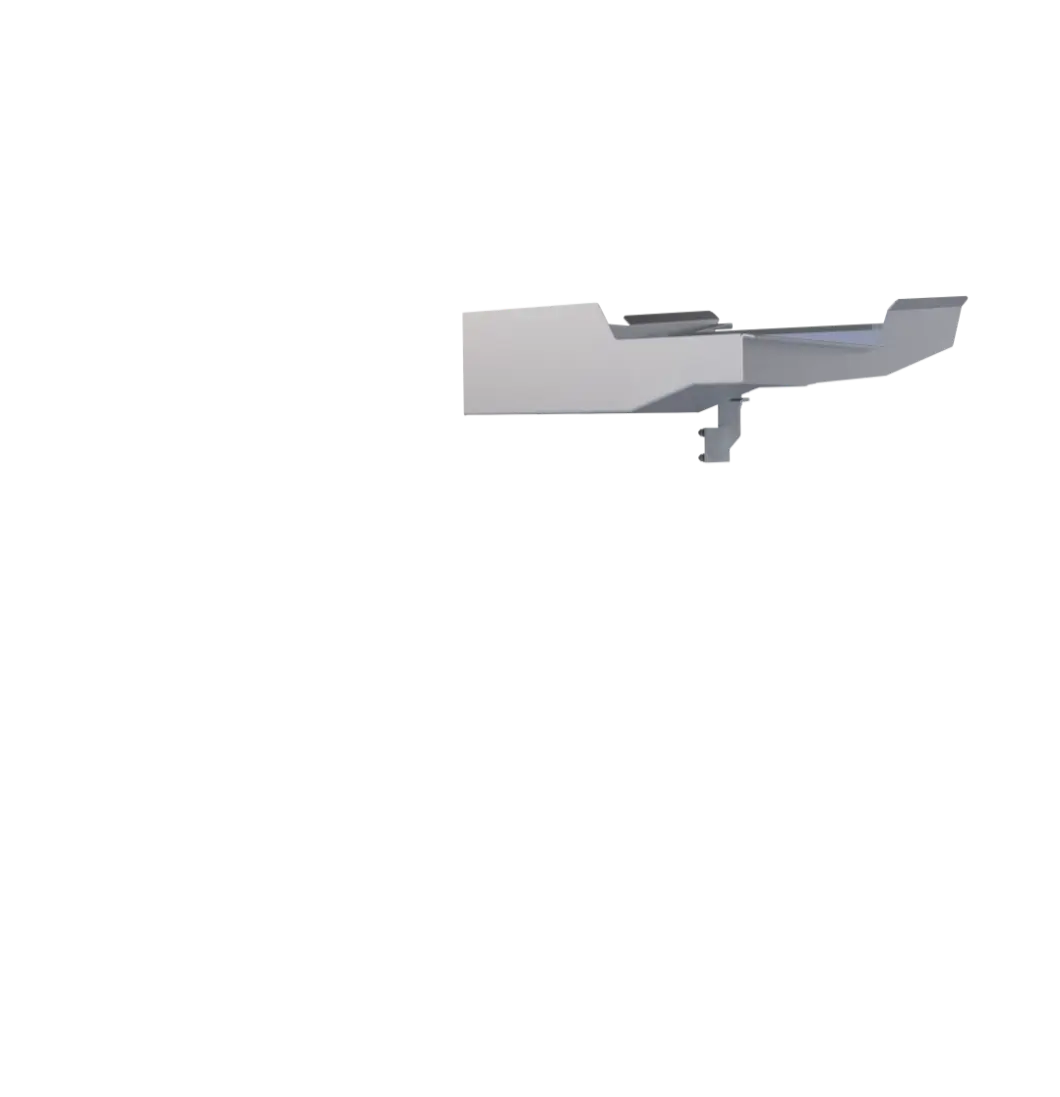

Technology Inside

Innovated to outperform.

AllMaxx S is powered by AF’s proprietary technology — engineered for gentle processing and real-world production, not lab specs.

- FlexxPress® pneumatic pressure system – optimized yield with no thermal or mechanical stress

- Smart Drum chevron pattern – directional flow for less belt wear and more usable output

- TecBelt® platform – flexible, hygienic belts for every product type

Tech Specs

Throughput

500 kg/h up to 5 t/h, depending on product type and drum configuration

Motor

3 kW with variable speed adjustment

Separation Technology

Soft-belt compression (FlexxPress®) for efficient, gentle separation

Drum Material

High-grade stainless steel with hygienic design, supporting tool-free disassembly

Drum Perforation Sizes

1 mm, 1.3 mm, 2 mm, 3 mm, 5 mm, and 8 mm — customizable

Belt Thickness Options

Offered in 10 mm and 13 mm (other sizes available on request)

Feeding Options

Available with optional Hopper Infeed for automated feeding or manual infeed for flexible, small-scale processing.

Optional Features

Pusher for handling larger products

Automatic lubrication pump

Standard control panel for straightforward, reliable use

External communication interface (e.g., for integration with existing plant systems)

Hygienic Design

All components are designed for sanitary use, with smooth surfaces, easy access, and full wash-down compatibility — without tools.

Footprint

Compact, mobile construction (on wheels), making integration into new or existing lines easy.

Videos

Discover the most important features, benefits, and real‑world applications of the AllMaxx S in our top video selections.

We’ve Got You Covered

Expert care. Global reach.

From startup to long-term uptime, we support your machine with OEM parts, preventive programs, and fast-response technicians.